Thrust Bearings

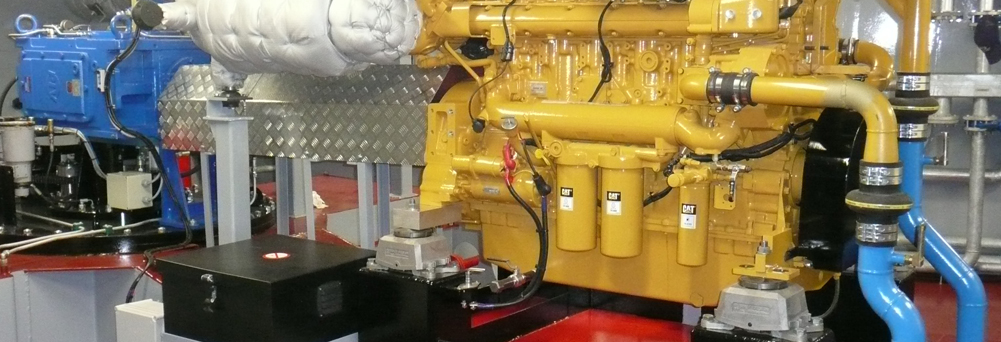

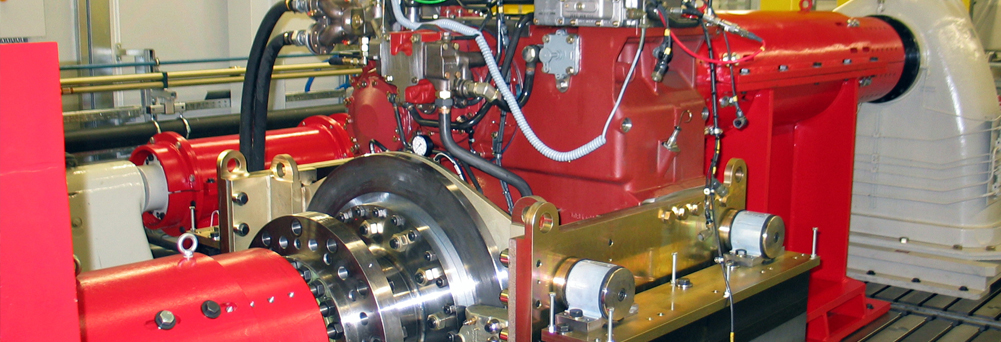

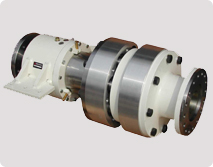

Rubber Design has developed a compact range of thrust blocks in combination with their ERD Marine Couplings for high performance operation in yachts and ships.

The advantage of using a thrust block is that the propeller thrust load is not taken by the engine-gearbox. This way an optimised flexible mounting system of engine-gearbox can be used, which gives the best results for vibration isolation and reduction of structure borne noise from engine-gearbox to the foundation (hull of the ship). Structure borne noise is transmitted quickly through the hull and causes disturbing noise (resonance) in areas outside of the engine room, this can cause problems or discomfort.

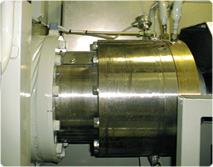

To obtain the best results in the reduction of structure borne noise, the thrust block has a further option to be flexible mounted with a minimum deflection in the longitudinal direction. An advantage of using the ERD marine coupling is that torsional vibrations and noise transmission from the engine-gearbox to the thrust block is reduced. During assembly the thrust shaft is accurately aligned and fixed with transit bolts before dispatching to the customer. Due to this fixture and the four alignment bolts it is a very easy process to achieve an accurate alignment with the propeller shaft.

CAD drawings (2D/3D) of the thrust blocks and ERD marine couplings are available in different formats so that this geometry can be easily imported into the CAD drawing of the complete propeller shaft installation. All thrust blocks and ERD marine couplings can be delivered with the required classification approval.

联系我们:

Rubber Design B.V.

Head Office

Industrieweg 21

2995 BE Heerjansdam

The Netherlands

China Representative Office

中国办事处

中国江苏省南京市

栖霞区中山门大街699号

565室

邮编:210049

Latest News

- Rubber Design opens branch office in China19 July 2017 - 09:34

NMT important export partner for Rubber Design22 September 2015 - 08:57

NMT important export partner for Rubber Design22 September 2015 - 08:57 Project Rubber Design aan boord van MPS VistaPrima2 June 2015 - 16:07

Project Rubber Design aan boord van MPS VistaPrima2 June 2015 - 16:07